WHAT IS A DELTA ROBOT?

A delta robot, otherwise known as a parallel robot, is a commonly used robot in pick and place and packaging applications. The design and construction of the delta robot lends itself to extremely fast picking and placing of a variety of parts. Most delta robots consist of three arms connected to universal joints at the base and are driven by coordinated servo control. It is this lightweight construction and low inertia that allows the servo control to achieve the very high pick and place rates.

PRODUCTS

PRODUCTS

MANUFACTURERS

AUTOMATION SOLUTIONS

INFO CENTER

ABOUT US

SCHEDULE A

DEMO

With the addition of a vision system, a delta robot becomes an extremely flexible pick and place tool. Vision adds the ability to track the position of parts on a conveyor and anticipate the precise picking location. Parts can now be picked at any location or orientation on the conveyor and be placed into a variety of locations, including into a package, onto a pallet or another conveyor, and many other applications.

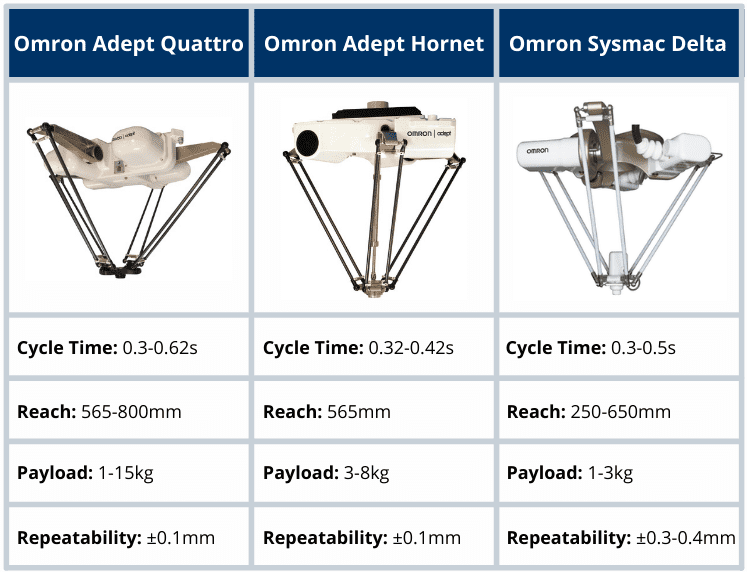

Mechatronic Solutions is a Tier 1 distributor of Omron’s robotic solutions including three series of delta robots (Quattro, Hornet, and Sysmac) that all provide integrated vision conveyor tracking

Mechatronic Solutions is an automation distributor for Minnesota, Wisconsin, North Dakota, and South Dakota, with a large selection of delta, multi-axis, collaborative, SCARA, and mobile robots available. We have a team of automation specialists and engineers on staff to provide application assistance and to help you find the best solution for your project. For more information or to speak with a member of our team, fill out the contact form or call Mechatronic Solutions at (763) 447-3407.