Omron Robotics

Omron has a robotics line-up that can solve any automation challenge.

Their Robot line-up includes:

SCARA, Delta, 6-axis, Collaborative & Mobile combined with control, safety & more

What is a Collaborative Robot, or cobot? What are cobots used for?

What Are Articulated Robots Used For?

What Are Parallel Robots Used For?

What is a SCARA Robot? What does SCARA stand For?

SCARA robots are used in applications where parts need to be moved from one position to another that do not require any additional articulation aside from being rotated. Their speed enables them to be good choices for simple material handling applications such as pick and place as well as packaging. Their high level of accuracy and rigidity also make them well suited for basic assembly processes and dispensing.

What Are Mobile Robots Used For?

Industries Best Suited

| Material Handling | Metal Working | Life Sciences |

| Packaging Industry | Automotive Industry | Cleanroom |

| Logistics | Manufacturing | Food / Bev |

| Palletizing | Arc Welding | Pick and Place |

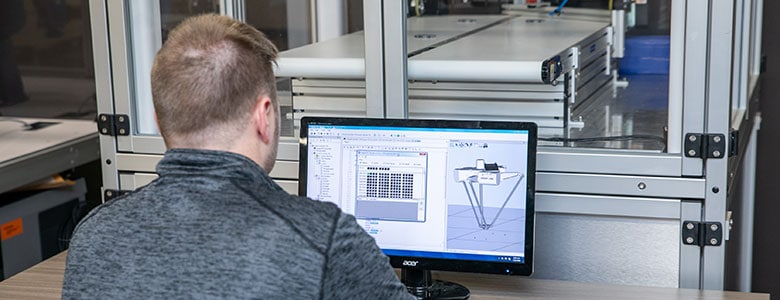

ACE Software

ACE software provides an easy-to-use environment to program and deploy applications ranging from simple pick & place to multi-robot belt-tracking lines. It allows you to increase productivity while streamlining configuration setup. ACE 4.0 shifts to an even more intuitive interface and provides superior data visualization.

Who is Mechatronic Solutions?

Mechatronic Solutions is a distributor of OMRON automation products and solutions for Minnesota, Wisconsin, North Dakota, and South Dakota. We have a team of technical experts on staff to help select the right automation products for your application. If you have any questions or would like to speak with a member of our team, contact us at (763) 447-3407 or fill in the Contact Form.

Why Omron Robotics?

Omron has developed a wide range of robotic solutions that can help you improve your business processes.

“Omron Robotics is a leading provider of collaborative robots that are safe, easy to use, and adaptable to a wide range of applications.”

What is Omron Safety for Robotics?

Omron is also a leader in machine safety through their acquisition of STI or Scientific Technologies Inc. They generate safety measures such as hard guarding, light curtains, proximity sensors and much more.

Feasibility Testing

Proof of concept or feasibility testing is an important part of Mechatronic’s approach to providing high quality solutions and exceptional results for our customer’s automation projects. Mechatronic Solutions has an experienced team of Application Engineers and an Automation Solutions Center with extensive demo equipment to conduct testing.

APPLICATION SOLUTIONS FOR ROBOTIC & COBOT SOLUTIONS

- Assembly

- Machine Tending

- Picking, Packing, Palletizing

- Welding (Arc Welding & Spot Welding)

- Product Inspection

- Screw-driving

- Gluing

- Labeling

- And more

6 AXIS INDUSTRIAL ROBOT PRODUCTS

- Omron Adept Viper 650/850

SCARA ROBOT PRODUCTS

- Omron Adept ECobra & Cobra series

PARALLEL/DELTA ROBOT PRODUCTS

- Omron Adept Quattro, Hornet, Sysmac Delta Series

COLLABORATIVE (COBOT) ROBOT PRODUCTS

- Omron TM Series with built-in vision – TM5-700, TM5-900, TM12, TM14

MOBILE ROBOTS FROM OMRON

- LD Series

CONTACT MECHATRONIC SOLUTIONS TODAY

Need robotic & collaborative robot (cobot) solutions in Minnesota, Wisconsin, North Dakota, or South Dakota… Call Mechatronic Solutions at 763-447-3407 or fill in the Contact Us form today to work with our application engineers or schedule a demo.