ATX Trade Show 2022 - Virtual Booth!

The Omron TM to the Omron LD

The TM robot interfaces with an Omron NX102 PLC to which an Omron NA-Series HMI is connected. The HMI provides users multiple options where the selection passes through the PLC and reaches the TM, at which point the TM performs a field inspection, picks the selected option and then places this item on a tray on top of the Dorner 2700-series conveyor. This floor-mounted Dorner conveyor will then send the item to another Dorner 2700-series conveyor mounted on top of the Omron LD-Series mobile robot.

The Mobile Robot then delivers the users selection to them at the point of selection before returning the tray to the original conveyor, thus completing the cycle.

The Products Showcased

- Omron TM Cobot

- Omron LD Mobile Robot

- Dorner 2700 Conveyor

- Robotiq Hand-E Gripper

- Omron NX102

- Omron NX1P2

The Omron TM to the Omron LD

The TM robot interfaces with an Omron NX102 PLC to which an Omron NA-Series HMI is connected. The HMI provides users multiple options where the selection passes through the PLC and reaches the TM, at which point the TM performs a field inspection, picks the selected option and then places this item on a tray on top of the Dorner 2700-series conveyor. This floor-mounted Dorner conveyor will then send the item to another Dorner 2700-series conveyor mounted on top of the Omron LD-Series mobile robot.

The Mobile Robot then delivers the users selection to them at the point of selection before returning the tray to the original conveyor, thus completing the cycle.

The Products Showcased

- Omron TM Cobot

- Omron LD Mobile Robot

- Dorner 2700 Conveyor

- Robotiq Hand-E Gripper

- Omron NX102

- Omron NX1P2

The Omron i4L

The Omron Sentech Camera identifies parts and objects within the Asyril Asycube 240. If the parts are not in the correct orientation for picking, the Asycube will vibrate the position to match the correct alignment. The Omron i4L then picks the pieces out of the cube and places them in their correct location.

The Products Showcased

- Omron i4L

- Omron Sentech Camera

- Omron ACE Sight Software

- Asyril Asycube 240

The Omron i4L

The Omron Sentech Camera identifies parts and objects within the Asyril Asycube 240. If the parts are not in the correct orientation for picking, the Asycube will vibrate the position to match the correct alignment. The Omron i4L then picks the pieces out of the cube and places them in their correct location.

The Products Showcased

- Omron i4L

- Omron Sentech Camera

- Omron ACE Sight Software

- Asyril Asycube 240

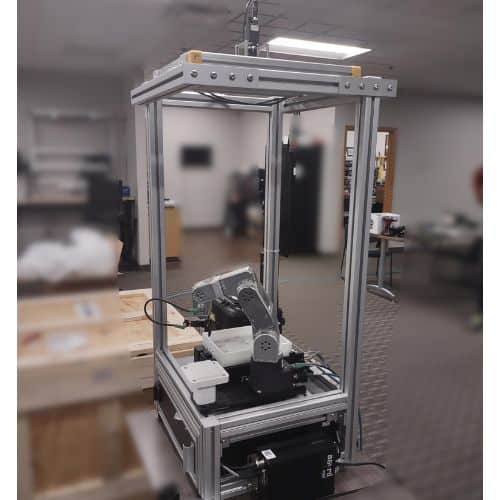

The Asyril Eye+ Demo

The Asyril Eye+ is responsible for determining the correct orientation of the part being picked as well as its proximity to other parts so as to avoid collision.

The Asycube will precisely vibrate the parts into an optimal position so the Meca500 can pick the part and place it in the original location.

For this demo, the loop is closed by the Meca500 which places the parts back in the cube before beginning the sequence again.

This demo is powered by an Omron NX1P2 and is presented on an Omron NA5 HMI.

Additionally, the frame is customized with a TSLOTS extrusion frame.

The Products Showcased

- Asyril Eye+ Camera

- Asyril Asycube

- Mecademic Meca500

- Omron NX1P2

- Omron NA5 HMI

- TSLOTS Extrusion

The Asyril Eye+ Demo

The Asyril Eye+ is responsible for determining the correct orientation of the part being picked as well as its proximity to other parts so as to avoid collision.

The Asycube will precisely vibrate the parts into an optimal position so the Meca500 can pick the part and place it in the original location.

For this demo, the loop is closed by the Meca500 which places the parts back in the cube before beginning the sequence again.

This demo is powered by an Omron NX1P2 and is presented on an Omron NA5 HMI.

Additionally, the frame is customized with a TSLOTS extrusion frame.

The Products Showcased

- Asyril Eye+ Camera

- Asyril Asycube

- Mecademic Meca500

- Schunk MEGP 25E

- Omron NX1P2

- Omron NA5 HMI

- TSLOTS Extrusion

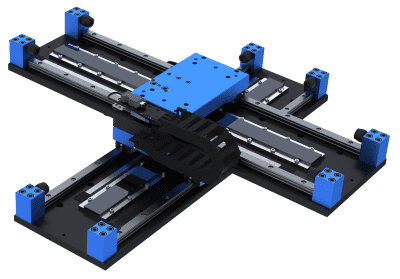

Bell-Everman

ServoBelt™ Linear actuators redefine the classic belt drive, putting belts to work in an entirely new way that reduces the positioning errors and speed limitations of conventional belt drives.

ServoBelt™ Rotary is a series of compact, high-torque motorized rotary stages that offer through hole size and speed comparable to direct-drive rotary tables costing thousands more.

The Products Showcased

- Bell-Everman ServoBelt Linear

- Bell-Everman ServoBelt Rotary

Bell-Everman

ServoBelt™ Linear actuators redefine the classic belt drive, putting belts to work in an entirely new way that reduces the positioning errors and speed limitations of conventional belt drives.

ServoBelt™ Rotary is a series of compact, high-torque motorized rotary stages that offer through hole size and speed comparable to direct-drive rotary tables costing thousands more.

The Products Showcased

- Bell-Everman ServoBelt Linear

- Bell-Everman ServoBelt Rotary

The Yaskawa and Allen-Bradley Connection

Yaskawa Sigma 7 Compact Servo Drives are compatible with Allen Bradley PLC’s using AOIs & EtherNet/IP. To showcase this we have set up two different demos to the same root products to showcase the versatility of the pairing.

A SigmaTrac II is running SigmaLogix to move the metal example to and fro. Using Vibration dampening, the motor is able to pre-determine the jostle and balance it for minimal jiggle.

Using a Festo EGC, we are moving the Mecademic Meca500 between two different positions on the axis so that it could pick parts from two different locations outside of it’s default range.

The Products Showcased

- Allen Bradley PLC

- Yaskawa Sigma 7 Drive

- SigmaTrac II

- SigmaLogix Software

- Festo EGC

- MecaDemic Meca500

The Yaskawa and Allen-Bradley Connection

Yaskawa Servo Drives are compatible with Allen Bradley PLC’s with AOIs & EtherNet/IP. To showcase this we have set up two different demos to the same root products to showcase the versatility of the pairing.

A SigmaTrac II is running SigmaLogix to move the metal example to and fro. Using Vibration dampening, the motor is able to pre-determine the jostle and balance it for minimal jiggle.

Using a Festo EGC, we are moving the Mecademic Meca500 between two different positions on the axis so that it could pick parts from two different locations outside of it’s default range.

The Products Showcased

- Allen Bradley PLC

- Yaskawa Sigma 7 Drive

- SigmaTrac II

- SigmaLogix Software

- Festo EGC

- MecaDemic Meca500

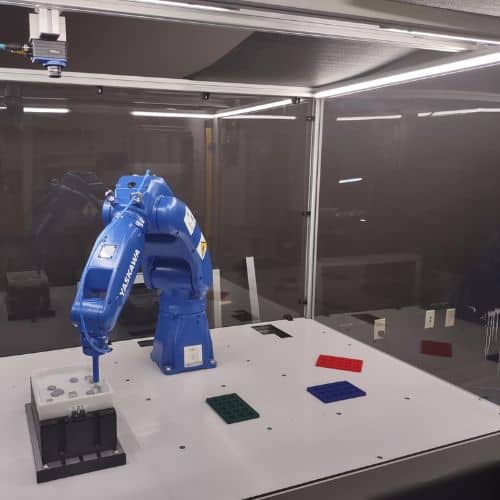

The Motoman GP8

The Motoman GP8 will pick parts from the Asycube and place them within the designated tray using the Motosight software.

To ensure safety while working in an open cell, we are using Omron F3SG-SR Light Curtains and the Omron OS32C Area Scanner.

The housing for the safety equipment was built using TSLOTS extrusion.

The Products Showcased

- Yaskawa Motoman GP8

- Asyril Asycube

- Omron F3SG

- Omron OS32C

- Yaskawa MotoSight 2D

- TSLOTS Extrusion

The Motoman GP8

The Motoman GP8 will pick parts from the Asycube and place them within the designated tray using the Motosight software.

To ensure safety while working in an open cell, we are using Omron F3SG-SR Light Curtains and the Omron OS32C Area Scanner.

The housing for the safety equipment was built using TSLOTS extrusion.

The Products Showcased

- Yaskawa Motoman GP8

- Asyril Asycube

- Omron F3SG

- Omron OS32C

- Yaskawa MotoSight 2D

- TSLOTS Extrusion

Conveyors Made Easy

The Dorner 2200 creates a streamlined process for you to move your products from A to Z. The Eaton Easy e4 Relay is a cost-effective solution to add logic to the conveyor.

Most Dorner conveyors are shipped with an all-in-one system or modular so you can add what you need to make it your own.

This conveyor system is also using a Lenze VFD and has additional TSLOTS extrusion for quick and easy mounting.

The Products Showcased

- Dorner Conveyors

- Eaton Easy e4 Relay

- Eaton HMI

- Lenze VFD

- TSLOTS Extrusion

Conveyors Made Easy

The Dorner 2200 creates a streamlined process for you to move your products from A to Z. The Eaton Easy e4 Relay is a cost-effective solution to add logic to the conveyor.

Most Dorner conveyors are shipped with an all-in-one system or modular so you can add what you need to make it your own.

This conveyor system is also using a Lenze VFD and has additional TSLOTS extrusion for quick and easy mounting.

The Products Showcased

- Dorner Conveyors

- Eaton Easy e4 Relay

- Eaton HMI

- Lenze VFD

- TSLOTS Extrusion

The Hornet Parallel Robot

The Hornet, in conjunction with Omron’s Ace software, synchronizes with the machine vision and conveyor to pick the products off the line and place them where needed.

The robot cycle time is ~.37 seconds which give this demo a great speed showcase.

The Products Showcased

- Omron Adept Hornet

- Omron D4FL – Safety Limit Switch

- Omron D4NS – Safety Switch

- Omron ACE Sight Software

- Omron VFD

- TSLOTS Extrusion

The Hornet Parallel Robot

The Hornet, in conjunction with Omron’s Ace software, synchronizes with the machine vision and conveyor to pick the products off the line and place them where needed.

The robot cycle time is ~.37 seconds which give this demo a great speed showcase.

The Products Showcased

- Omron Adept Hornet

- Omron D4FL – Safety Limit Switch

- Omron D4NS – Safety Switch

- Omron ACE Sight Software

- Omron VFD

- TSLOTS Extrusion

Asyril 10L Hopper

The 10L Hopper is filled with parts that need sorting. The Eye+ checks for orientation and proximity to other parts. The Asycube will shake the parts for the Precise Robot to pick and Place.

The Products Showcased

- Asycube 380

- Asycube 240

- Asyril Eye+

- 10L Hopper

- Precise Robot

Asyril 10L Hopper

The 10L Hopper is filled with parts that need sorting. The Eye+ checks for orientation and proximity to other parts.

The Asycube will precisely vibrate the parts for the Robot to pick and Place.

The Products Showcased

- Asycube 380

- Asycube 240

- Asyril Eye+

- 10L Hopper

- Precise Robot

The GP4 and Schmalz Vacuum Generator

Using the Yaskawa Motoman Smart Pendant, we don’t need Machine Vision for this fixed position demo.

The Smart Pendant has precise dimensions for the GP4 to locate. The Schmalz SCPSi helps generate a vacuum for the pneumatic suction end effector. This process picks and places between both positions and cycles back.

There is a TSLOTS extrusion frame to prevent human interaction and an Omron OS32C to modify speed and activity based on human proximity.

The Products Showcased

- Yaskawa Motoman GP4

- Schmalz SCPSi

- Omron OS32C

- TSLOTS Extrusion Frame

The GP4 and Schmalz Vacuum Generator

The Yaskawa Motoman pendant creates an accessible viewpoint for the user to quickly modify the logic required for fixed-position pick and place.

The Schmalz SCPSi helps generate a vacuum for the pneumatic suction end effector. This process picks and places between both positions and cycles back.

There is a TSLOTS extrusion frame to prevent human interaction and an Omron OS32C to modify speed and activity based on human proximity.

The Products Showcased

- Yaskawa Motoman GP4

- Schmalz SCPSi

- Omron OS32C

- TSLOTS Extrusion Frame

The Yaskawa Motoman HC10

The HC10 Cobot is designed for Assembly and Handling, so we created a demo around the simplicity of setup.

The HC10 is trained using the Smart Pendant, so no machine vision is required for finding and picking the parts.

The Schmalz FQE XC end effector will adhere the box to its grippers as the HC10 picks from position A and places to position B.

The Products Showcased

- Yaskawa Motoman HC10

- Schmalz FQE XC

- Yaskawa Motoman Smart Pendant

The Yaskawa Motoman HC10

The HC10 Cobot is designed for Assembly and Handling, so we created a demo around the simplicity of setup.

The HC10 is trained using the Smart Pendant, so no machine vision is required for finding and picking the parts.

The Schmalz FQE XC end effector will adhere the box to its grippers as the HC10 picks from position A and places to position B.

The Products Showcased

- Yaskawa Motoman HC10

- Schmalz FQE XC

- Yaskawa Motoman Smart Pendant

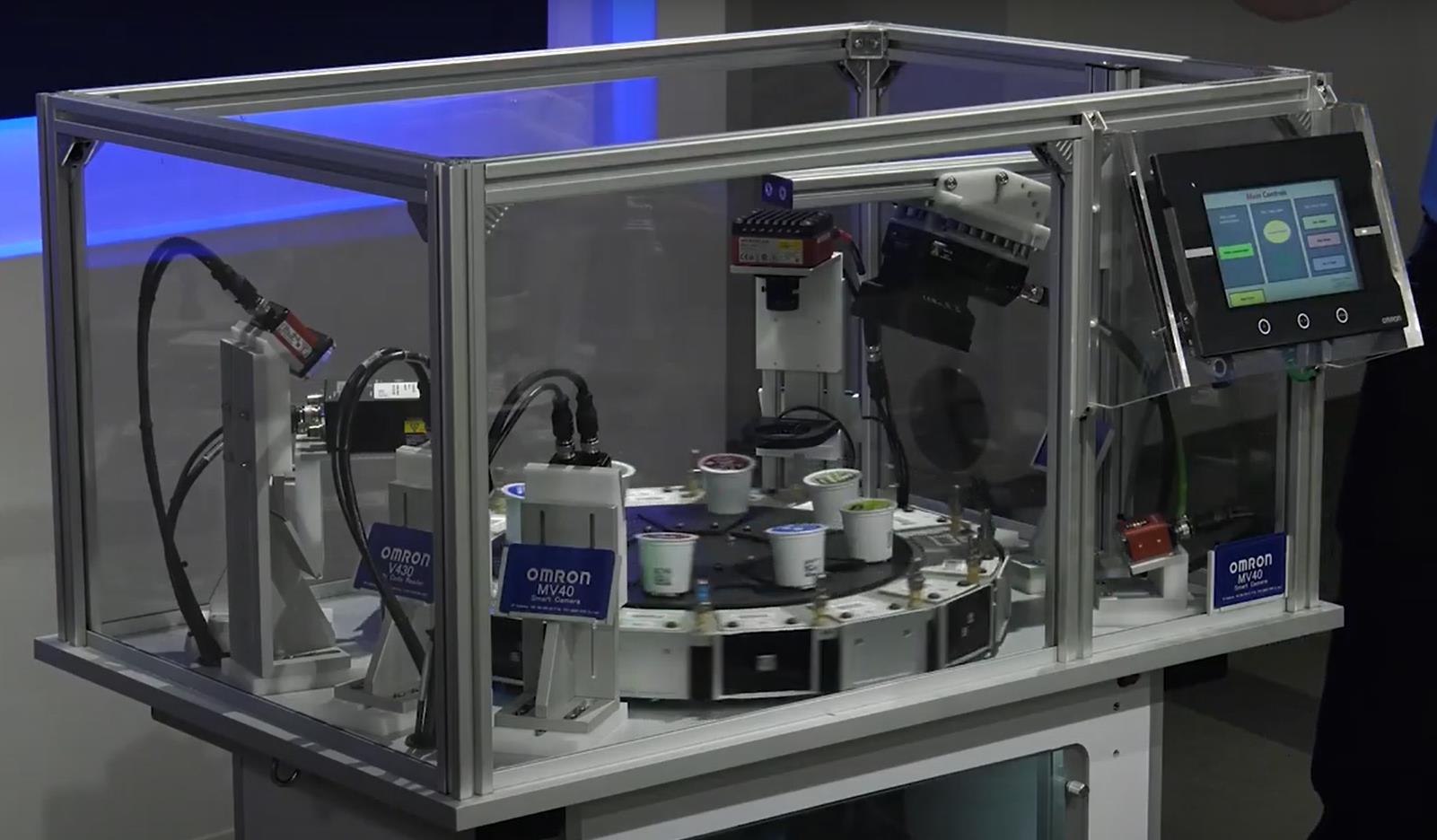

The Omron Fishtank Demo

This demo showcase Omrons automation and traceability solutions for your code reading and vision quality inspection needs within the food & bev packaging industries.

The FHV7 is a modular smartcamera with various attachments per application. The FHV7 also has ProfiNet, Ethernet, and Ethercat connections.

The Omron NA HMI is programmed in the same environment of the PLC, which is connected to the Servo 7 Motor by EtherCat.

The Products Showcased

- Omron FHV7 Camera

- Omron MicroHawk v430

- Omron MicroHawk f430

- Omron ID-45

- Omron MV40

- Omron 1S Servo Motor

- Omron NX1P2

The Omron Fishtank Demo

This demo showcase Omrons automation and traceability solutions for your code reading and vision quality inspection needs within the food & bev packaging industries.

The FHV7 is a modular smartcamera with various attachments per application. The FHV7 also has ProfiNet, Ethernet, and Ethercat connections.

The Omron NA HMI is programmed in the same environment of the PLC, which is connected to the Servo 7 Motor by EtherCat.

The Products Showcased

- Omron FHV7 Camera

- Omron MicroHawk v430

- Omron MicroHawk f430

- Omron ID-45

- Omron MV40

- Omron 1S Servo Motor

- Omron NX1P2

Enter For A Chance to Win Wild Tickets!

Enter using the form here for a chance to see the Minnesota Wild play against the Pittsburgh Penguins on November 17th at 7:00 P.M.!