NEWS

Product News

Much of the growth is fueled by demand for mobile robots for a range of applications across various industries. Mobile robots are widely used in the logistics, warehousing, and manufacturing sectors, however, demand from the medical and health sectors is also on the rise.

Mobile Robot Application Examples

Below are a few examples to give you an idea of how mobile robots can be deployed:

Manufacturing Facility

Transporting raw materials such as metal, plastic, or rubber from receiving to the production line to ensure they always have what they need without interruption.

Medical Facility Logistics

Delivering supplies or medications from designated storage areas to the hospital/care room where they are needed.

Warehousing

Moving pallets of boxes from the receiving area to where they need to be stored, or vice versa, bringing goods that need to be shipped up to the receiving area.

Hazardous Material Handling

Handling materials, products, or chemicals that may be dangerous to a human worker or completing tasks where the actual environment may be hazardous.

Types of Mobile Robots: AGVs vs. AMRs

Around a decade ago, automated guided vehicles (AGVs) became an alternative to conveyors for material handling. Until recently, they were the only option. Today, however, autonomous mobile robots (AMRs) are challenging AGVs. So, how are they different?

AGVs require a predefined path to follow, such as either a network of magnetic lines on the floor or beacons on the walls. So, although AGVs allow modifications to production lines, facilities will need to install new equipment every time the AGV path needs to be changed, which leads to extra costs and downtime.

AMRs on the other hand can safely navigate around facilities without the use of magnetic lines on the floor or wall-mounted beacons. They first create a baseline map of a facility using built-in sensors and then they are constantly able to adapt to their surroundings. When a production line or process changes, an AMR can easily change with it, creating a network of new routes or being deployed for new tasks. AGVs will stop at obstacles indefinitely until they are moved, while AMRs avoid moving or stationary obstacles and automatically reroute themselves when necessary.

AMRs’ paths automatically change without any intervention, making operations more flexible and decreasing the cost of ownership.

Mobile Robot Solutions

Omron LD Series Mobile Robots

Omron’s mobile robot solutions are very versatile and can be adapted to perform a wide variety of tasks and applications. Omron’s LD Series mobile robots are self-navigating AMRs designed for dynamically moving material in challenging environments such as confined passageways as well as dynamic and populated locations. There are three different models in the LD series:

- LD 60 (60kg payload)

- LD 90 (90kg payload)

- LD 250 (250kg payload)

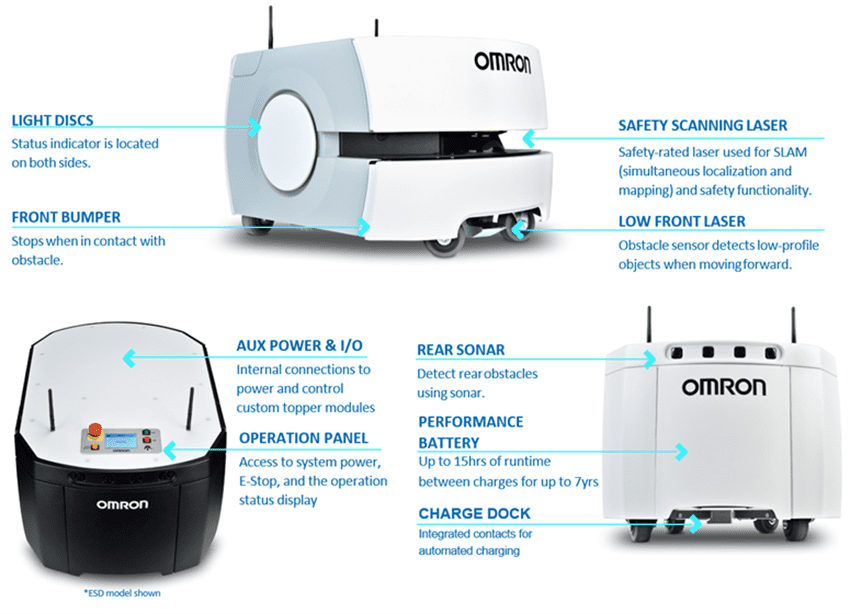

LD 60/90 Features

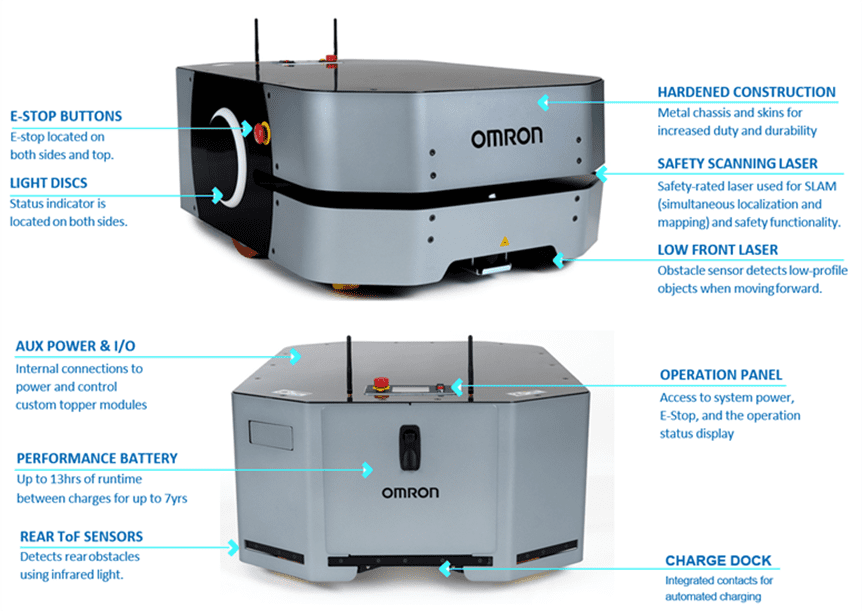

LD 250 Features

Omron HD-1500 Series Mobile Robot

Omron’s HD-1500 mobile robot boasts a payload of 1,500kg and handles the performance of simple transport, delivery, and routing operations so your employees can perform higher-value jobs. The high payload allows users to automate new tasks that were not previously possible, such as the transport of pallet-size loads, engine blocks, and other heavy goods/materials.

Contact Mechatronic Solutions

Mechatronic Solutions is a leading industrial robotics company for Minnesota, Wisconsin, South Dakota and North Dakota. We have a team of application engineers on staff and an extensive Automation Solutions Lab for demonstrations and proof-of-concept testing. If you have any questions or would like more information, please fill out our contact form and a member of our team will reach out to you.

PRODUCTS

PRODUCTS

MANUFACTURERS

AUTOMATION SOLUTIONS

INFO CENTER

ABOUT US

SCHEDULE A

DEMO