ROBOTIC WELDING SYSTEMS

Motoman Welding Robot Systems

Mechatronic Solutions is a leading provider of Yaskawa Motoman robotic welding systems. For over three decades, Yaskawa Motoman has developed more welding robots, sensors, software and positioners than any other company.

Our highly knowledgeable engineering staff helps take the fear out of automating your welding operations by providing direct support through the process from planning to implementation and supplying training to your team.

ArcWorld robotic welding systems from Yaskawa Motoman are turnkey solutions for arc and spot welding. They are pre-engineered, pre-assembled, and shipped out ready for use. ArcWorld systems are compatible with leading welding equipment manufacturers, including Miller, Lincoln Electric, Fronius, and SKS.

PRODUCTS

PRODUCTS

MANUFACTURERS

AUTOMATION SOLUTIONS

INFO CENTER

ABOUT US

SCHEDULE A

DEMO

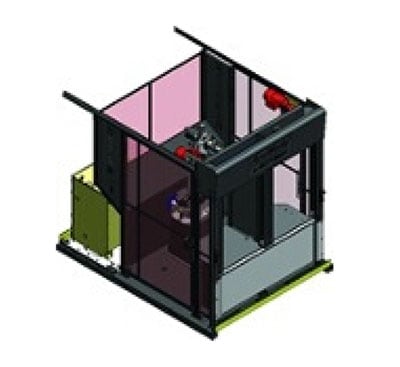

ArcWorld 50 Series

- Extremely compact workcell

- Ideal for small- to medium-sized parts

- Wire-to-weld solutions

- Available in single or dual station configuration

- ArcWorld 50 Series Datasheet

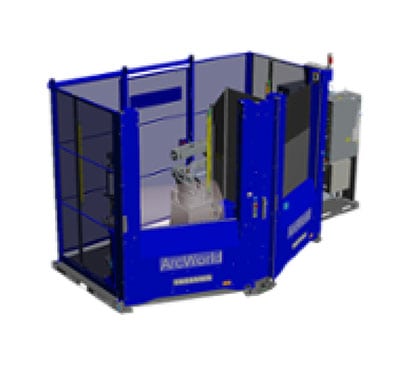

ArcWorld 200/500

- More robust capabilities than compact cells

- Ideal for small- to medium-sized parts

- Wire-to-weld solutions

- Ideal for medium to high volume applications

- ArcWorld 200-500 Series Datasheet

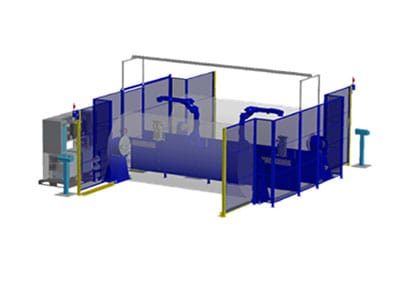

ArcWorld 2000

- Heavy-duty solution

- Ideal for large parts and heavy-deposition welds

- Available in single or dual station configuration

- Modular and scalable

- ArcWorld 2000 Series Datasheet

- High robot utilization

- Parts can be loaded/unloaded at operator station while robot processes parts internally

- Sealed/auto-lubricated drives

- ArcWorld 6000 Series Datasheet

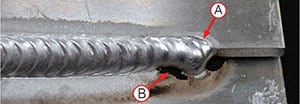

There are many reasons to automate your welding operations, the biggest is the major labor shortage of skilled welders. The American Welding Society projects that by 2023 there will be a shortage of over 375,000 welders. Another reason is the consistent high-quality welds that robots can deliver. There’s no more time spent grinding sub-par welds, less scrap, and higher quality outputs.

Bad Human Weld Example

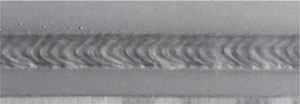

Robotic Weld Example

Lastly, the cost of robotic welding systems is more affordable than ever. With a lower investment and large improvements in both productivity and quality, the return on investment is significant.

Resources

Yaskawa Motoman Robotic Welding Solutions Catalog

Yaskawa Motoman ArcWorld Welding Cells Video

Contact Mechatronic Solutions

Interested in learning more about our automated welding systems? Call Mechatronic Solutions at 763-447-3407 or fill in the Contact Us form today to speak with an engineer!