AUTOMATION PROJECT FEASIBILITY TESTING

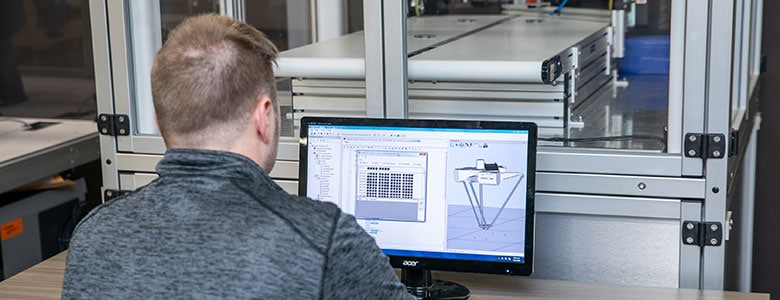

Proof of concept or feasibility testing is an important part of Mechatronic’s approach to providing high quality solutions and exceptional results for our customer’s automation projects. Mechatronic Solutions has an experienced team of Application Engineers and an Automation Solutions Center with extensive demo equipment to conduct testing.

TYPES OF FEASIBILITY OR PROOF OF CONCEPT TESTING

Future Products

Robotic Cycle Rate, Including Conveyor Tracking

Mechatronic Solutions has an Automation Solutions Center with multiple types of robots to run testing.

Example:

A large food manufacturer was looking to implement a parallel/delta robot solution into their plant to pick products from a conveyor and package them into boxes for shipping. The cycle rates for the robot needed to be tested to ensure that it would be feasible for this project. Our team set up a mock cell at our facility and were able to provide ballpark cycle rates. This was a full study that spanned a few weeks as it involved customer tooling and extensive program refinement. We then brought the customer out to Yaskawa Motoman’s U.S. headquarters to conduct further testing on the exact robot they were looking to buy. This solution is currently in use at the customer’s plant.

Flexible Parts Feeding

Customers frequently come to our facility to test their parts on our Asyril feeders. Many of them are surprised at how simple it is to tune the feeder optimally for their part, and how well it works in comparison to other feeding technologies. Additionally, having access to the Asyril U.S. headquarters in Edina, MN provides us many more options for testing and feasibility studies.

Machine Vision & Inspection

Our vision experts can conduct testing to see whether your machine vision or inspection application is feasible, what products or equipment should be used, and provide you with a solution.

Example:

A customer had a cylindrical part they needed to perform measurement and OCR testing on. The measurements they needed to take were fairly simple diameter measurements. However, the OCR they needed to test was written along the perimeter of the flat face on the cylindrical part making it difficult. To solve this, we utilized a new software to take an image of the entire part and isolate an annular slice, then run the OCR tool on only that portion of the image. This enabled the customer to successfully perform their measurements and testing.

Vacuum Systems

Mechatronic Solutions offers a variety of vacuum lifting systems and vacuum end of arm tooling for robots. Our team can conduct testing to ensure that you receive the optimal solution for your vacuum application.

Motion Control Performance

Our application engineering team will work through testing for your motion control systems.

Example:

A customer wanted to use Yaskawa servos to run a CNC application, thus needed to use G-Code in the Yaskawa controller. Our team worked with Yaskawa on the brand-new (at the time) function blocks for executing G-Code with a set of grouped axes, including getting a custom function block written for FTP file transfer. The end result of this proof of concept was that all the customer needed to do was load a USB stick with their G-Code files and plug it into an HMI. Once they selected the desired file, the servos would run a CNC using interpolated motion.

Robotic End of Arm Tooling

Our application engineering team specializes in robotics and provides robotic end of arm tooling feasibility testing in our Automation Solutions Center. We have a large selection of grippers and tools for any robot. Our team will conduct testing to ensure that you have the best solution for your application.

PRODUCTS

PRODUCTS

MANUFACTURERS

AUTOMATION SOLUTIONS

INFO CENTER

ABOUT US

SCHEDULE A

DEMO

TALK TO AN APPLICATION ENGINEER TODAY

Feasibility and proof of concept testing for automation projects for Minnesota, Wisconsin, North Dakota, or South Dakota. A team of highly trained application engineers are ready to ensure success with your automation projects. Call Mechatronic Solutions at 763-447-3407 or fill in the Contact Us form today to reach our engineers.