IS FLEXIBLE FEEDING RIGHT FOR YOU?

Flexible feeding is a relatively new automation technology gaining traction in recent years due to constantly changing market demands and trends. For example, with the mass customization trend, consumers expect personalization to meet their individual needs while still expecting high quality and fast delivery. Another example comes from the ongoing COVID-19 pandemic. Certain products have seen demand skyrocket while others have seen demand completely fall off, causing manufacturers to quickly adjust their production lines. All of this requires a great deal of flexibility from manufacturers, making flexible manufacturing systems more important than ever.

Industry Needs & Challenges

Bulk is the most commonly used packaging method- Most companies receive at least some of their product in bulk. While this is a cost-effective way to receive product, it can become a challenge when fully automating a process.

Industry is asking for flexible solutions that can evolve over time- Production tools/systems must be designed with future applications in mind and be capable of accepting part design changes.

Production lines must be designed before the product itself- Creates the need for universal feeding solutions, not just one dedicated solution.

PRODUCTS

PRODUCTS

MANUFACTURERS

AUTOMATION SOLUTIONS

INFO CENTER

ABOUT US

SCHEDULE A

DEMO

Types of Part Feeding

Different technologies exist and each has its own advantages and disadvantages:

When Should Flexible Feeding Be Used?

High Mix/Low Volume: Frequent part design or production changes which require you to be flexible. You don’t want to have to redesign your bowl feeder or feeding system every time, you want it to be able to adapt.

Fragile Parts: Fragile parts don’t tend to do very well in a bowl feeder while flexible feeders are very gentle with parts.

Parts That Tend to Stick or Block: Parts that may block bowls or rails can cause issues and hold up production. This can be completely avoided by using flexible feeding.

No Part Design: When you don’t have the part design yet but must provide a solution, flexible feeders are the only option. Because flexible feeders can be implemented in pretty much any application and adapt to just about any part, you can design that into your production line and not have to worry about whether the part will work.

Short Production Time: Will you be producing the same thing in 12 to 18 months? Is it going to be a long-term part or are you going to be changing parts? If it’s going to be a shorter cycle time, then you will definitely want to look at flexible feeding.

Industry-Leading Flexible Feeders

The Asycube series of flexible feeding systems from Asyril are for parts and components from <0.1mm up to 150mm in size. Their innovative 3-axis vibration technology can handle bulk parts of any geometry and allows for extremely gentle part feeding.

Asycube Features & Benefits

Feed parts of any shape & material: 99% of parts can be fed by Asycube feeders, including complex geometries and highly delicate parts.

Detect parts with high precision: Asycubes come with an integrated backlight in your choice of color (red, green, white, blue, and infrared) that can be easily adjusted for precise part detection.

Achieve a faster cycle time: With Asyril’s 3-axis vibration technology, parts can be moved in all directions, do not accumulate in a corner or an edge, do not need to recirculate, and are gently handled by precise tuning of flipping amplitude.

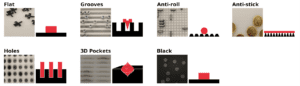

Consistently orient parts correctly: Asycubes can be fitted with a variety of structured platforms to guarantee a swift and correct orientation of parts.

Reduce changeover time: Structured plates of the Asycube can be changed quickly in under a minute and new vibration recipes can easily be configured.

EYE+ Smart Control System: New from Asyril, EYE+ allows you to control your hopper, Asycube feeder, camera, and robot from the EYE+ Studio, a web-based interface.

Mechatronic Solutions is a leading distributor of Asyril flexible feeding systems for Minnesota, Wisconsin, North Dakota, and South Dakota. We have an extensive Automation Solutions Lab that has a large selection of feeders, robots, vision, and more, which we use to provide proof-of-concept/feasibility testing to help deliver exceptional results for our customer’s automation projects. If you’re interested in learning more or would like to see a demo, contact us today!