COMBATING THE LABOR SHORTAGE IN MANUFACTURING

PRODUCTS

PRODUCTS

MANUFACTURERS

AUTOMATION SOLUTIONS

INFO CENTER

ABOUT US

SCHEDULE A

DEMO

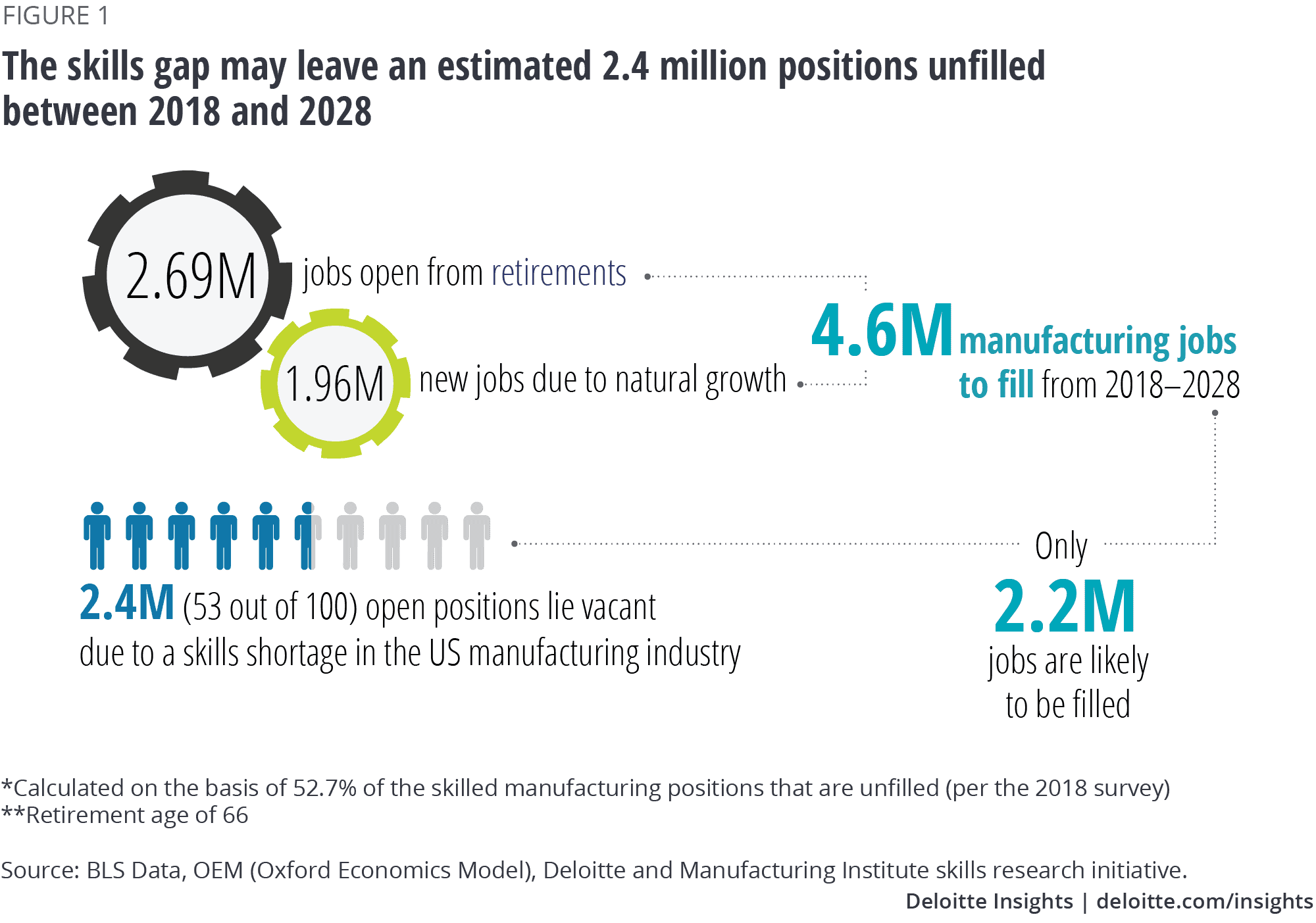

As the economy has been recovering, pent-up demand has resulted in a boom for many sectors. However, many companies are leaving revenue on the table due to an inability to fully meet demand because of a lack of staffing.

So, how can manufacturers address the labor shortage and maximize their success? There probably isn’t just one right answer, and the best solution probably includes multiple initiatives that work together to address the problem. Although the mix will vary by company, a strategic focus on these three areas will likely be the best way to address this issue: recruiting, retaining, and automating.

Recruiting

Why would people want to work at your company? Having a major point of differentiation for your company, and advertising that effectively is extremely important. Whether that’s offering competitive wages, training and growth opportunities, a fun working environment, or something else, is for your company to decide. Additionally, building relationships with local high schools and tech schools can be a great way to build a pipeline that continually refreshes itself with new workers entering the workplace. Lastly, partnering with a staffing agency can enhance your recruiting efforts and take a lot of the burden off your company.

Retaining

Once you’ve found a qualified recruit and hired them, the work isn’t done. If you don’t work to retain your employees, then you’ll find yourself in the same cycle of continually hiring for the same positions which wastes a lot of time and money. Keeping current employees engaged is a must. Providing ongoing training and mentoring is an effective way to help employees feel valued as an important part of the company. Additionally, maintaining a positive work environment and strong company culture is crucial in keeping employees engaged and increasing employee retention.

Automating

Utilizing automation technology, particularly robotics, is an effective way to alleviate the labor shortage. While robots and other forms of automation (conveyors, motion control, actuator systems, etc.) often receive negative press for “taking jobs”, the truth is there are not nearly enough skilled workers to fill the number of available jobs as we’ve discussed. Robotics and automation are not only a popular solution due to their efficiency, flexibility, and ability to deliver a solid ROI, but they also require skilled technicians, maintenance, engineers and other higher value positions to deploy these systems and keep them running. Robots are used basically everywhere in today’s manufacturing processes for a variety of applications, including assembly, pick and place, packaging, palletizing, material handling, inspection, machine tending, welding, and more. In addition to traditional industrial robots which include multi-axis, mobile, parallel/delta, and SCARA robots, collaborative robots have been an increasingly popular solution because of their ability to share a workspace with humans and augment their capabilities.