I Have A Project To Pick And Place Components In A Clean Room

Ask an Engineer

Question:

“In 2023, we are looking to remove operators from the cleanroom environment or incorporate more automation that can streamline production. We do not wish to disclose what it is we are producing, but it is a medical device that requires an ISO 14644 cleanroom grade. What are some products to consider when starting out with pick & place automation in cleanrooms, and what are some key factors to keep in mind during the planning process?”

PRODUCTS

PRODUCTS

MANUFACTURERS

AUTOMATION SOLUTIONS

INFO CENTER

ABOUT US

SCHEDULE A

DEMO

Jesse Janson, Sales Engineer at Mechatronic Solutions.

“First, you want to identify the underlying reasons why you want to automate the process. In today’s environment, the most common reasons I see include:

- Difficulty finding workers to perform the job reliably and consistently

- The process itself may be hazardous, dangerous, or repetitive leading to long term injuries

- Production rates need to increase to meet demand

From the high-level reasoning, you can probe further by asking “Why?” again to uncover more detailed information.

“I’ll highlight three common applications for automation in a cleanroom: Pick and Place Assembly, Moving Materials, and Pipetting/Liquid Handling.”

Pick and Place Assembly

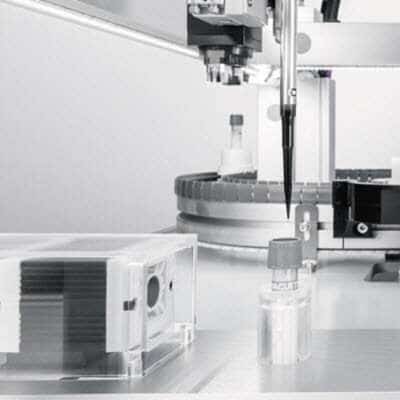

Most pick and place assembly applications simply utilize a robot to grip a component from a pallet, bin, cassette, or part feeder and place it into an assembly, fixture, or machine.

“Depending on the size of the object and the application requirements, I will recommend either a cartesian system, a SCARA (4-axis), or an articulating (6-axis) robot. In the past I have deferred to using an Omron eCobra, however they have just released a cleanroom certified i4H SCARA that outperforms the eCobra.”

“Depending on the number of functions you need it to do and the orientation requirements of the components, Omron’s six-axis Viper could also be a viable option.”

Material Handling

Manually moving product through a fab or lab continuously over an 8 hour shift is an exhausting task especially while wearing suits, shoe covers, and gloves the entire time. Automated material handling through the facility can look much different clean room to clean room. Mobile robots known as AGV’s (Autonomous Guided Vehicles) or AMR’s (Autonomous Mobile Robots) are a great way to deliver products between machines or WIP locations across an entire facility automatically or through simple operator request buttons. The Omron LD90 and LD250 are autonomous mobile robots with ISO-Class 5 rating that can move products between workstations without interfering with lab technicians.

Conveyor systems, such as Dorner’s portfolio of cleanroom certified conveyors are a good option for larger-scale production.

Pipetting and Liquid Handling

“Regarding Pipetting and Liquid Handling, we have already extensively covered some of the solutions and how to best determine which step is right for you.”

Watch our Webinar Replay: “Liquid Handling for Lab Automation Presented by Festo”

“There are countless steps and intricacies in a setup, I hope that my answer gave you some decent starting points to consider as you continue developing your system. “

Mechatronic Solutions

Mechatronic Solutions is a leading provider of Automation Technology in South Dakota, North Dakota, Minnesota, and Wisconsin. If you need cleanroom or lab automation, feel free to reach out, and one of our specialists can assist you in your workflow.