Automating Your Pipetting Solutions

In this article, we will map out some different avenues for you to take when upscaling your pipetting process with automation. Topics covered will be:

- Where pipetting technology stands today

- The different types of automation available

- Factors to consider before choosing your next steps

- Starting points in technological upgrades

Pipetting as it Exists and Transitions Today

Pipetting technology is always at the forefront of innovation in the healthcare space. Whenever there are opportunities to streamline production, it is applied to lab work and lab technicians.

As such, the standard steps for pipetting automation are typically dictated by the inclusion of lab techs vs. the requirements of the applications in the long-run.

As such, pipetting automation typically has three categories:

Manual, Semi-Automatic, and Automatic.

The Various Types of Pipetting Automation Available Now

PRODUCTS

PRODUCTS

MANUFACTURERS

AUTOMATION SOLUTIONS

INFO CENTER

ABOUT US

SCHEDULE A

DEMO

Manual

Manual Pipetting is the standard for the task. Therefore, there is a technician handling a pipette in their hands as they transport a solution to various samples.

Then there is the transportation of these samples from their environment to the centrifuge for processing.

Finally, there is data documentation, which could be seamlessly integrated into a computer or manually inputted by the technician.

Semi-Automatic

In Semi-Automatic pipetting, the most popular step to increase throughput is utilizing a pipetting gun. There is a device that the technician uses that automatically produces the desired solution into the desired sample.

This removes the dexterous strain on the lab technician and can be scaled to service up to 10 samples at the same time, exponentially increasing the amount administered by the tech.

The lab technician can still handle the transport and data documentation of the samples without any changes.

Otherwise, mobile robotics and collaboratives could be added to ease the transport while machine vision and scanners could add in data documentation and traceability features.

Festo Fully Automatic

There are numerous plays on how to automate the pipetting process fully, and to showcase this, I’m going discuss how two of our vendors Festo & Omron handle fully automating the pipetting process.

Festos Completely Automatic System [ See Right ]

There is a central robotic arm that pivots between the two systems.

On the left is a single pipetting system that involves a small conveyor, to act as a centrifuge.

On the right, a full pipetting system with an XYZ gantry for the precise motion of liquid handling.

Omron’s Completely Automatic System

Disclaimer: This is done in conjunction with Grips Technology out in Germany.

The PT600 (in the video) features two SCARAs working in unison. One handles a pipetting end effector, while the other has an end effector for handling the caps.

Two cameras are present: the gigabit ethernet vision cameras and the microhawk series, renowned for its tracing capabilities.

Factors to Consider for Adding Automation to your Pipetting Process

Accuracy and Reliability

Humans make human errors. Administering too much solution, mishandling/mislabeling samples, and input errors in data; there are numerous factors that can go wrong with a manual lab tech that can be automated.

Throughput

There are limitations to how many samples a single human can responsibly handle. If the samples per hour are increasing exponentially, then so does the amount of tasks, which means more people or more efficient processes featuring automation.

Data Management

Processing and handling your data is an important cornerstone of good lab automation. How many rote processes can be streamlined with automation? This would free up many more resources for your on-site technicians to work more efficiently problem solve.

Recommended Starting Points for Pipetting Automation

For Pipetting: Festo’s DHOE and DHOP.

These are two excellent pipetting systems that should be the centerpiece of any lab automation. As is typical with many Festo products, they are highly configurable and modularly adaptable.

Festo DHOE and Festo DHOP

For Robots: Omron’s i4H and the Meca500.

Coming in Spring 2023, the i4H now has a cleanroom model that is ready for the world. Their predecessor (the eCobra) was featured in the above Omron video, but the upgrade is available by the time you’re ready to take the next step.

Alternatively, the Meca500 is the world’s smallest mini-six-axis robot. This means it is highly articulate, repeatable, and accurate; while boasting a fantastic form factor.

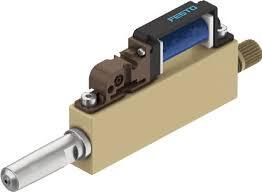

For Linear Motion: Festo

Festo provides numerous actuators and gantries that are highly customizable and cleanroom rated.

For Machine Vision: Omron

Omron has end-to-end offerings for traceability. All of their hardware seamlessly integrates and registers the data as they are being processed and are among the elite in the industry.

What does the future look like From Here?

The future is looking bright. Frequently, we are seeing more end-to-end solutions from vendors such as Festo and Omron.

Here is another example system provided by Festo that comprehensively covers the opening, dispensing, pipetting, and transporting of fluids.

With cloud-based integrations for data handling and enhanced traceability solutions, the footprint of each tech is getting smaller by the day.

Mechatronic Solutions

Mechatronic Solutions is a premier provider of Omron and Festo products in the Upper Midwest: Minnesota, Wisconsin, North Dakota, and South Dakota. If you need automation assistance with your lab or cleanroom, do not hesitate to contact us!