Partner Spotlight

Bell-Everman

Bell-Everman, Inc. was founded in 1991 with the goal of creating motion devices that offer best-in-class precision, quality, and value. Since then, their motion control solutions have been incorporated into a wide variety of automation and metrology systems – including in the aerospace, biomedical, electronics, packaging, semiconductor, laser and water jet cutting, and CNC machining industries.

All of their products are designed and built in their own facility in Goleta, CA. Today, their product line includes precision linear bearings, linear motion positioning devices, rotary stages, and complete multi-axis robotic systems.

Bell-Everman Products & Solutions

Rotary Positioning

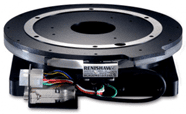

ServoBelt™ Rotary (SBR) stages are a series of compact, high-torque motorized rotary stages that offer through hole size and speed comparable to direct-drive rotary tables that cost thousands more. These stages offer large through holes (50mm, 100mm and 200mm) to accommodate bundles of power, signal and pneumatic conductors, as well as standard through holes (16mm and 25mm) for a more economical choice when less utilities need to pass through.

SBR stages support both continuous rotation and variable indexing applications. They are designed for NEMA 23 and 34 motors and will offer speeds up to 1,000rpm, continuous torque to 6.6Nm and resolution down to 0.16 arc-sec with Renishaw ring encoders or tape scales for partial rotation.

Direct Drive Theta (DDT) rotary stages feature a compact mechanical design that makes them easy to integrate with machines that need precision positioning and metrology systems. They’re available in two sizes – the DDT 100 has a 15mm through hole and the DDT 200 has a 50mm through hole, both offer plenty of space to bring power and utilities to the top of the stage.

DDT stages offer exceptional angular alignment capabilities – the DDT 100 model has an accuracy of ± 12 arc-sec, while the DDT 200 offers an accuracy of ± 6 arc-sec. Both models have a bi-directional repeatability of ± 1 encoder count.

DDT stages have been engineered with extremely fine preload adjustments, allowing users to maintain consistent motor tuning. An aluminum construction with stainless steel hardware also makes them a rugged and durable solution.

Linear Positioning

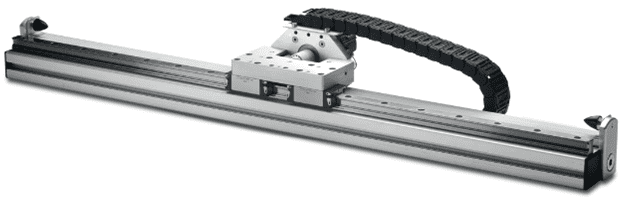

ServoBelt™ Linear (SBL) actuators redefine the classic belt drive by putting belts to work in an entirely new way that reduces the positioning errors and speed limitations of conventional belt drives. Unlike a conventional single-belt drive, the SBL’s carriage rides between a pair of toothed, steel-reinforced polyurethane belts. The static belt is permanently bonded to an aluminum rail to form the ServoBelt’s structural chassis. The active belt runs over a driven pinion and through a set of idler rollers fixed inside ServoBelt’s moving carriage.

SBL actuators provide speeds up to 4m/s, accuracy to ±4µm/meter and bi-directional repeatability of ± 1 encoder count, comparing favorably to high-end linear motor drives that cost thousands more. They also provide unlimited scalability. With a chassis based on standard T-slot extrusion, SBL can be engineered for travel distances up to 50 meters to create large-format motion systems. A single SBL axis will also support multiple carriages with independent motion.

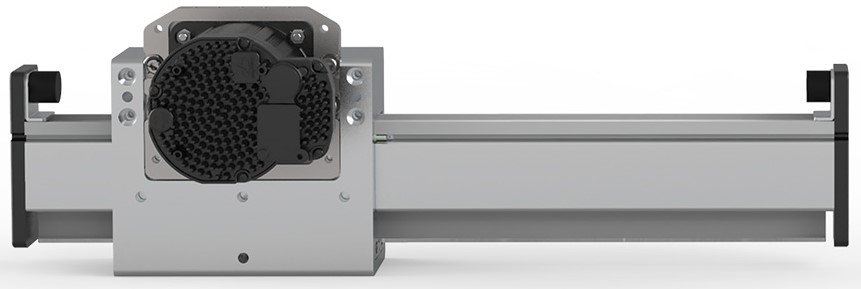

Based on their ServoBelt™ Linear (SBL) technology, the ServoBelt™ RA actuator serves as a high-performance drop-in replacement for applications that traditionally use rod actuators, pneumatic cylinders or even linear motors.

Unlike traditional rod actuators, ServoBelt RA is fully guided along its entire stroke, making it more resistant to off-axis loads and more stable in on-axis moves. It has been engineered for moving chassis installation in both horizontal and vertical Z-axis orientations. The drive unit features standard or custom mounting hole patterns to make it easy to integrate into your machines.

ServoBelt RA offers speeds up to 4m/s, accuracy to ± 4µm/meter, bi-directional repeatability as low as ± 25µm and linear forces up to 200N.

Bell-Everman’s LowBoy linear stages have five different drive mechanisms available in the same compact aluminum chassis, allowing you to choose the ideal price to performance ratio for your application. The drive offerings are lead screw, standard ball screw, precision ball screw, air-core linear motor or iron-core linear motor.

The stages span a bi-directional repeatability range of ±0.5µm for the linear motor models to ± 50µm for the lead screw. LowBoy linear stages use either an 80mm high by 120mm wide chassis (light version) or an 80mm high by 180mm wide chassis (medium version), both of which have an integrated cover to protect the drive mechanism from contamination. The stages are available in lengths up to 1020mm and can exert continuous linear forces as high as 1540N depending on the drive mechanism.

KAOS OEM two-axis positioning stages are based on cog-free linear motors and combine a differential-motion carriage and a primary carriage on a single rail. The patented design results in a fast, compact stage ideal for semiconductor, electronics, assembly and pick-and-place applications.

KAOS offers speeds of 4m/s, accelerations in excess of 4g, accuracy of ± 9µm and bi-directional repeatability of ± 2 counts of the KAOS’ direct reading encoders. Compared to a conventional stacked linear motor positioning stage, KAOS has only about 1/10th the moving mass, balancing linear motor size and acceleration.

Custom Engineered Solutions

Bell-Everman also excels in creating unique automation solutions that meet your application’s requirements using their standard linear and rotary stages as building blocks. These engineered systems are larger and more complex than their standalone stages and incorporate controls, critical safety features and custom components – all delivered in one turnkey package.

From gantry-mounted electromechanical assemblies to long-travel cartesian robots, Bell-Everman is capable of developing a wide variety of custom solutions. Below are a couple examples:

Long-Travel Packaging/Palletizing Gantry System

Custom Biomedical Gantry System

Bell-Everman Configuration Tools

Bell-Everman offers online configuration tools to improve your engineering experience. The configurator is available for their ServoBelt™ Rotary, Direct Drive Theta Rotary, ServoBelt™ Linear and LowBoy linear products. You are able to configure your solution, which will generate a CAD model of your configuration and allow you to request a quote. Below is a link to their configuration page:

Additional Links

Contact Mechatronic Solutions

Mechatronic Solutions is a leading Bell-Everman distributor for Minnesota, Wisconsin, North Dakota and South Dakota. We have a team of engineers and automation specialists on staff to provide assistance with your application and help you select the right solution. If you would like more information or have any questions, please fill out our contact form and a member of our team will reach out to you.

PRODUCTS

PRODUCTS

MANUFACTURERS

AUTOMATION SOLUTIONS

INFO CENTER

ABOUT US

SCHEDULE A

DEMO