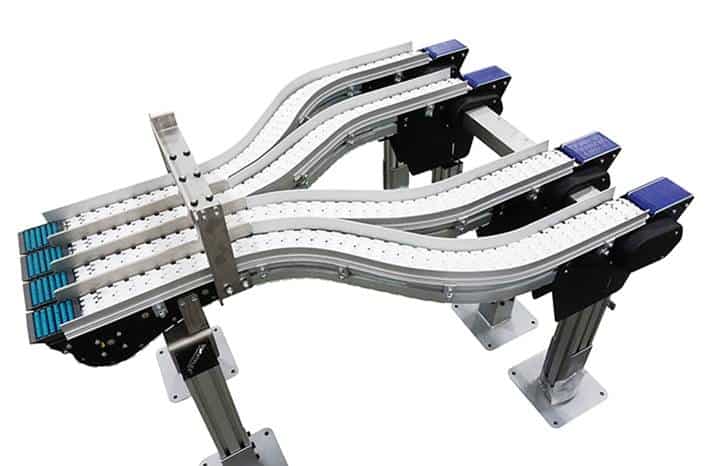

4 REASONS TO USE DORNER FLEXMOVE CONVEYORS FOR OPTIMIZING MATERIAL HANDLING PROCESSES

1. LAYOUT FLEXIBILITY – LIMITLESS OPTIONS

As mentioned, many companies are limited in the amount of available space in their facility and need greater flexibility in their equipment (especially conveyors). FlexMove conveyors provide the flexibility to fit exactly how you need them to, whether that includes tight turns, inclines and declines, or vertical 360° twists for an ultra-compact footprint:

PRODUCTS

PRODUCTS

MANUFACTURERS

AUTOMATION SOLUTIONS

INFO CENTER

ABOUT US

SCHEDULE A

DEMO

2. LARGE VARIETY OF APPLICATIONS IN JUST ABOUT ANY INDUSTRY

Dorner’s FlexMove conveyors can be configured exactly to your need and specification, with a variety of available sizes, chain types, modules, guiding, transfers, and more. Thus, making them an ideal fit for a number of applications and industries. Practical applications include:

Part Handling

Transfers

Tight Spaces

Assembly Automation

Packaging

Machine Conveyance

Elevation Changes

Accumulation

Buffering

Complex Configurations

Long Lengths

Curves, Jogs, Inclines, Declines

Companies from a variety of industries, ranging in size from small shops to large manufacturers, have seen the benefits of FlexMove conveyors:

Packaging

Food & Beverage

Retail

Medical

Industrial Automation

Health & Beauty

Life Sciences

General Manufacturing

Integrators

FlexMove conveyors deliver automation and enhanced functionality to your company, helping you grow and reach your goals. They free up your staff from working on monotonous, tedious jobs and allow them to focus their time and energy on higher-priority tasks which makes them more productive to your operation. They can also increase your production speed by running at up to 250ft per minute and offering industry best nose bar transfers for parts as small as 3” at speeds up to 200ft per minute. By transporting your products from point A to point B faster and more accurately, and freeing up your staff for other tasks, FlexMove conveyors are a great way to efficiently grow your business.

4. EASY TO CONFIGURE, PURCHASE & INSTALL

Dorner’s online configurator allows you to engineer simple or complex conveyors to meet your needs in minutes and delivers a 3D CAD assembly model for fit validation. The Mechatronic Solutions’ team is here to assist you with designing your conveyor system, just contact us to discuss your project. Every conveyor is completely assembled and tested at Dorner, then shipped in sub-assemblies to your facility. Dorner sets the industry standard for delivery with FlexMove conveyors available to ship in as little as 5 business days to get you running quickly!

LEARN MORE ABOUT DORNER FLEXMOVE CONVEYORS

Mechatronic Solutions is a leading distributor of Dorner conveyor systems and can assist you with your next conveyor project. Learn more about Dorner’s FlexMove conveyors or contact us today!